A New Standard

for R&D and Industry 4.0

Boost Performance, lower opertational costs, and ensure unmatched reliability

At Wormsensing, we’re revolutionizing vibration sensing and monitoring with unparalleled precision.

Our sensors are 1,000 times more sensitive than leading alternatives, detecting early-stage anomalies and subtle vibrations that conventional sensors often overlook.

By capturing critical data missed by traditional methods, Our sensors open new frontiers in design testing, monitoring, control, and operations—enhancing both efficiency and reliability. With our cutting-edge technology, manufacturers, integrators, operators, and insurers gain the confidence to optimize performance, innovate boldly, and ensure seamless operations with complete peace of mind.

Industries

| #Energy #Civil engineering #Industry 4.0 #Food Industry #Healthcare |

#Aerospace #Automotive #Transportation #Maritime Industry #Mining Industry |

CUSTOMER USE CASES

Satellite Vibration Testing | Airbus D&S

Setting new standadrs in satellite

vibration testing with Dragonfly®

↓ Download

Aerodynamic Testing | CREA

Measuring the influence of airflow on structures with Dragonfly®

↓ Download

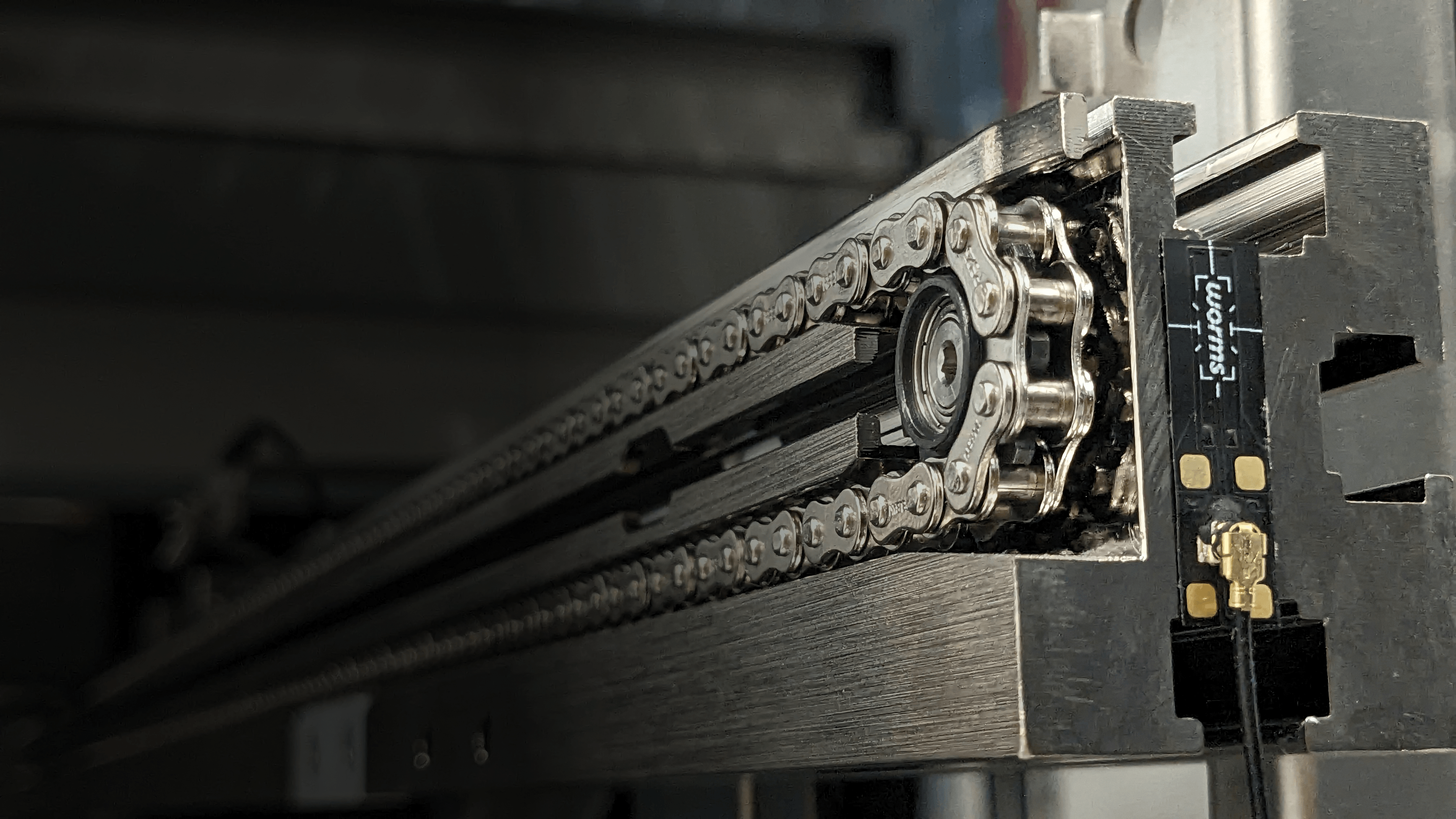

Rotating Machine | ifm electronics

Unprecedented insights into rotating machines with Dragonfly®

↓ Download

Split Hopkinson bar test | Gustave Eiffel University

Redefining Split Hopkinson pressure bar testing with Dragonfly®

↓ Download

Force Reconstruction | Vibratec

Unmatched accuracy in force reconstruction with Dragonfly®

↓ Download

Applications

Switch from preventive to predictive maintenance, save time, and lower your TCO

Our sensors unique features offer many advantages for both Structural Health and Condition Based Monitoring (SHM & CBM), or any essential continuous supervision:

– Very early signs of aging or indications of upcoming failure

– Predictive maintenance scheduling

– Support for decision-making concerning machines nearing their end-of-life.

This results in optimizing lifespan, increased safety and budget optimization.

1 Sensor, ∞ Events

Collisions, crack initiation, or leaks affect all materials and systems, and occur within a very wide frequency range.

Our sensors cover the complete frequency range (from quasi static to MHz) with unprecedented accuracy, simplifying instrumentation and measurement protocoles.

Get higher precision to make your model right

The diversity of vibration monitoring situations is endless, and requires vibration analysis expertise.

Experts operate for different reasons such as:

– Diagnosis

– Product development and design validation

– Materials characterization

– Cutting-edge R&D.

Our plug & play sensors fill a gap in today’s marketed solutions. Their non-invasiveness coupled with high sensitivity and large bandwidth make them a technology of choice to step vibration investigation further.

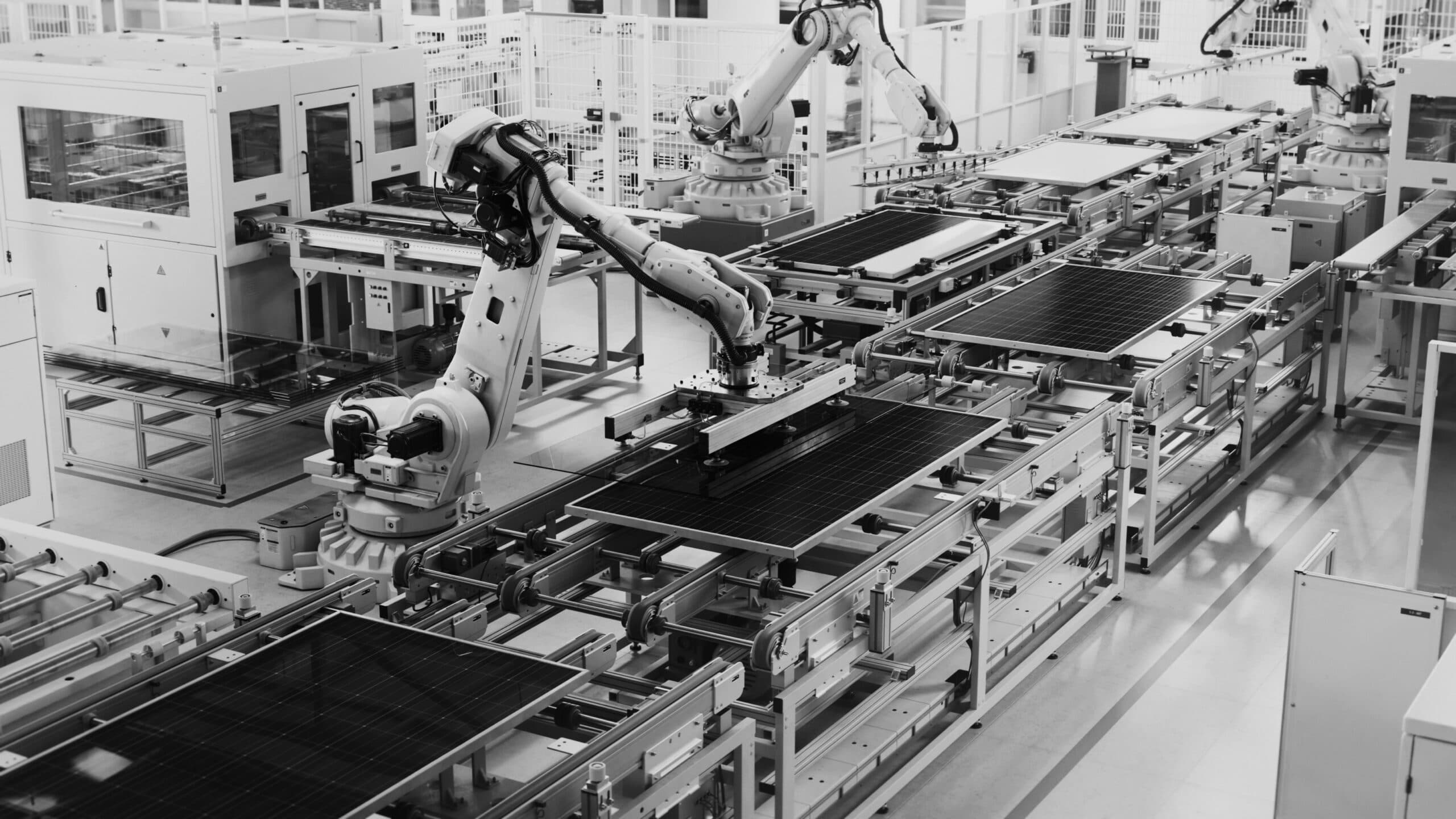

Gain control, optimize your production and increase yields

Monitoring vibrations on production equipment in manufacturing industries enables operators to make sure equipment are working in their nominal operating mode and are not subject to process drift.

It results in better production quality, increased yields, and enhanced safety for workers.

Increase throughput and sharpness

Dynamic weighing is a way to acquire data about different loads traveling through the equiped asset, such as bridge traffic or production line items.

Our technology can be used for dynamic counting. It can discriminate lighter loads to:

– Evaluate traffic

– Understand real induced stress on infrastructures

– Take corrective actions when needed

– Sort very light and very heavy items.

Make it touch-sensitive

Turning any surfaces (screens, parts, robots, co-bots, prosthetics, etc.) into a Human-Machine interface regardless of material composition (including metals), shape, and design is a dream come true with our technology.

Typical physical interactions with surfaces generate low levels vibrations only accessible with our technology today. With few sensing elements and simple electronics, the technology can provide interaction positions, force levels, and complex gestures recognition on large surfaces, unlocking the design of more intuitive and ergonomic systems.